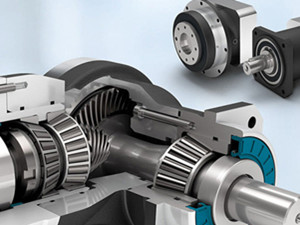

The oscillation of imported bearings has significant effects on bearing failure. For example, peeling, indentations, corrosion, cracks, and wear can be reflected in the oscillation analysis of imported bearings. Therefore, special equipment such as frequency analyzers and oscillation meters can be used to measure the magnitude of oscillation. By analyzing the frequency distribution, specific information about

690

Center Offset Method: For nonconforming dimensions (asymmetric defects) of the bearing raceway's inner and outer diameters, accurately measure the dimensions of the existing defects and calculate the small grinding allowance (the amount to be ground to achieve the final dimension), denoted as M. During the grinding process, offset the center of the workpiece towards the direction that increa

668

During the precision grinding of imported bearings, due to high requirements for surface roughness, the grinding marks on the working surface can often be observed with the naked eye. The surface grinding marks can be categorized as follows:

621

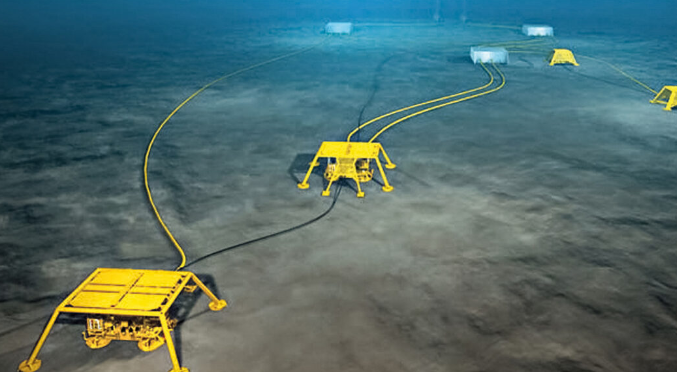

Active magnetic bearings from SKF are key components in today’s energy transition and optimization. Now they are finding applications in the technologies that will power a cleaner and more sustainable future.

665

To ensure the normal operation of FAG imported bearings, proper lubrication is essential. The rated load and maximum speed of rolling bearings are determined under the assumption of adequate lubrication. Adequate lubrication means selecting appropriate lubricants and using the correct amount. Poor lubrication is often one of the main causes of early bearing failure.

702